PMB MIXING PLANTS

The story of Menestrina and Polymer-Modified Bitumen (PMB) begins in the early seventies, when some clever Italian guys decided to test in industrial production the combination of the properties of given selected polymers with those of the industrial bitumen grades, for roofing and waterproofing applications.

That time has marked the beginning of a long story, still well alive today too.

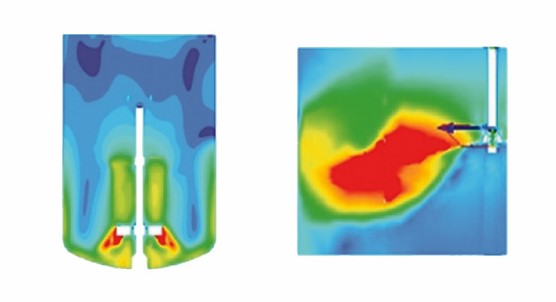

We have developed over the years a number of different mixing vessels, following the evolving requirements of the roofing producers. As soon as this tool has become available to the smaller-sized industry, we have immediately purchased and put to work an advanced CFD software package focused on the dynamics of mixing. Thanks to the analysis and simulation capabilities of this tool, we have been able to update and refine the design of our stirrers and vessels, achieving solid results in terms of performance and energy utilization.

Keeping the mixing units at the centre of the projects, we have developed around them a variety of peripheral systems, ranging from self-cleaning filters to static traps, from automatic heating/cooling thermo-controls to nested hot oil sub-loops for flexible heat distribution, and so on and so forth.

As the logic consequence of our long experience with PMB processing, as soon as the marketplace generated a demand for PMB grades for roads paving, we have been involved in this more recent world as well. Proud of counting a good part of the biggest and most important Italian producers of PMB road grades among our Customers, we are able to provide in this case too solutions of excellence.